Foundry Engineering & Project Management

What We Provide

- Foundry Layout and Design Services

- Complete Project Management and Installation if Desired

- Facility Laser Scanning and Modeling

- Equipment Fitment Within Existing Facilities or Greenfield

- Geotechnical Review

- PE Design Services

- Product Flow Analysis and Improvement

- Equipment Analysis and Specification

Key Benefits

Extensive foundry operations and foundry equipment experience.

Many years of hands on experience in foundries around the world.

No overcomplication, over design, or overselling our customers. We prefer simple, basic solutions based on good foundry practice. We leave bells and whistles to others.

Ability to take your concepts from your thoughts, to integrated design, to completed construction.

Foundry Capabilities

General Foundry Review

- Del Sol takes a straight forward review approach. We call our approach to foundry review "forest for the trees". For us, we can walk into your foundry, and since we do not live there, we can see process solutions you have been walking past for years. Often, we can help your operation and organization by simply being able to see and analyze the forest because we are not stuck within the trees.

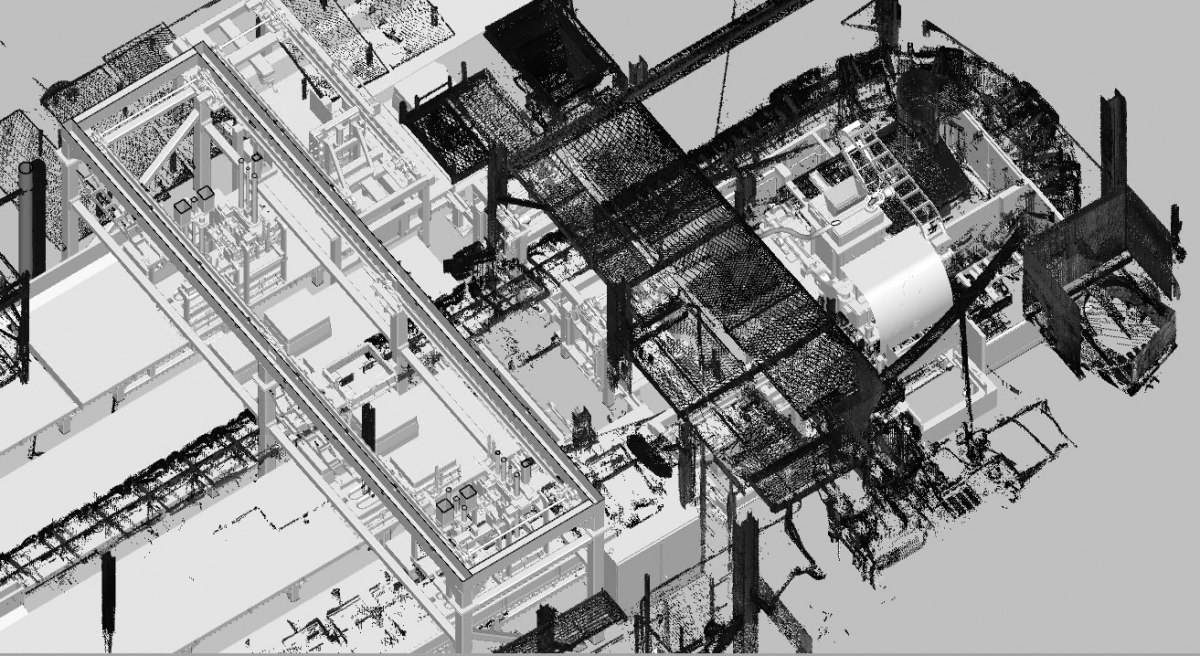

Facility Scanning and Modeling

- Del Sol has the ability to laser scan and provide for solid modeling of your plant and proposed equipment solutions. We are excited about this capability and the depth it brings to our engineering offering.

Below is a modeled shakeout and sand reclamation system for a proposed solution.

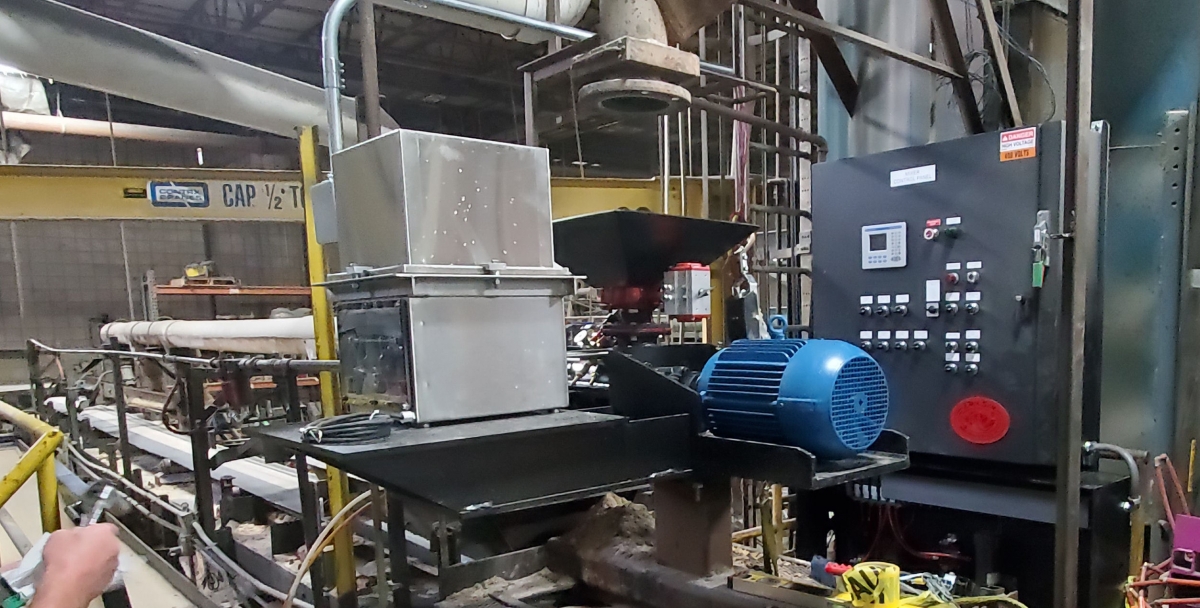

Below is the modeled solution being installed by our crews.

And finally, the finished product...

Civil Engineering - Construction - Installation

- Del Sol offers geotechnical evaluation and civil engineering for building and equipment foundations. This is an awesome addition to our design services and now allows us to go from concept to full installation.

Molding

- Del Sol offers functional airset and greensand molding design and review. Whether you need to update a few pieces of equipment, or need to design a brand new foundry, we have the experience to help.

- Significant experience in operations, equipment, and system design allow us to analyze and implement appropriate improvements in your foundry.

- We excel at visiting your foundry, gaining insight as to what you want to accomplish, reviewing current capabilities, and offering real, hands on solutions. Our specialty in molding system review is taking an existing system that needs improvement, upgrading it using best in class equipment selections, and adding the necessary equipment to accomplish your goals.

"Del Sol has the innate ability to analyze projects with an uncanny sense of forethought in a very short amount of time. You just don’t see that in people anymore."

-- Maintenance Superintendent, Major Midwest Steel Foundry

- We have direct experience with many molding system designs, layouts, and molding techniques - from fully automated systems to loose floor molding. Our hands-on equipment experience is second to none. We have truly hands on (dirty fingernails) experience in this realm and can help you with your needs.

Below is a superimposed image of a laser scan we performed laid over a solid model of a proposed molding system. This customer hired Del Sol to assure form, fit, and function.

and a piece that we installed based on this engineering work...

Sand Reclamation

- At the heart of any foundry is sand reclamtion. Del Sol offers design services and equipment for both mechancial and thermal sand recalamtion systems

60 TPH Mechanical System Installed by Del Sol below. Steel Foundry - Three Part Phenolic Urethane

6 TPH Thermal Sand Reclamation at one of our customer's facilities in Texas. Iron foundry. Three part phenolic urethane.

40 TPH Greensand Reclamation System in Kansas. Del Sol was responsible for fitment and installation.

Core Making

- Del Sol offers a wide range of experience with equipment and process solutions for core making - cold box, airset, and shell.

- From a simple gas generator selection to a fully integrated core production system, we can help.

- We in excel properly fitting appropriate core making equipment into a jobbing environment.

Cleaning Room Operations

- From shakeout to shipping, we have the experience needed to improve individual processes to complete flow revision.

- Cutoff, blast, grinding, robotic finishing, work cell design, are all areas of strength for our engineering team.

Need help?