Foundry Sand Mixers

Del Sol has extensive no bake experience and can help with any size project. From a simple core room mixer to a full airset molding system, Del Sol can help.

Available Models

- BFM100 (50-150 # / Minute) - CLICK FOR BFM100 OVERVIEW VIDEO

- BFM250 (100-250 # / Minute)

- BFM750 (300-750# / Minute) - CLICK FOR BFM750 OVERVIEW VIDEO

- BFM1500 (600-1500# / Minute)

- BFM2500 (1000-2500# / Minute)

BFM Series Mixers

Fundamentals

We build an extremely heavy steel fabrication, backed by an oversized mixing motor, fed by robust sand and resin feed devices, controlled by a modern yet simple control package. Why? So that your machine mixes sand every day, and if it breaks, your maintenance guys can fix it with their skill set. We have tried our best to deliver a machine that runs and doesn’t cause you grief. We left the fancy to others. We addressed the brutal environment in which you work with a machine that can handle it for the long run.

CLICK FOR BFM100 OVERVIEW VIDEO

CLICK FOR BFM750 OVERVIEW VIDEO

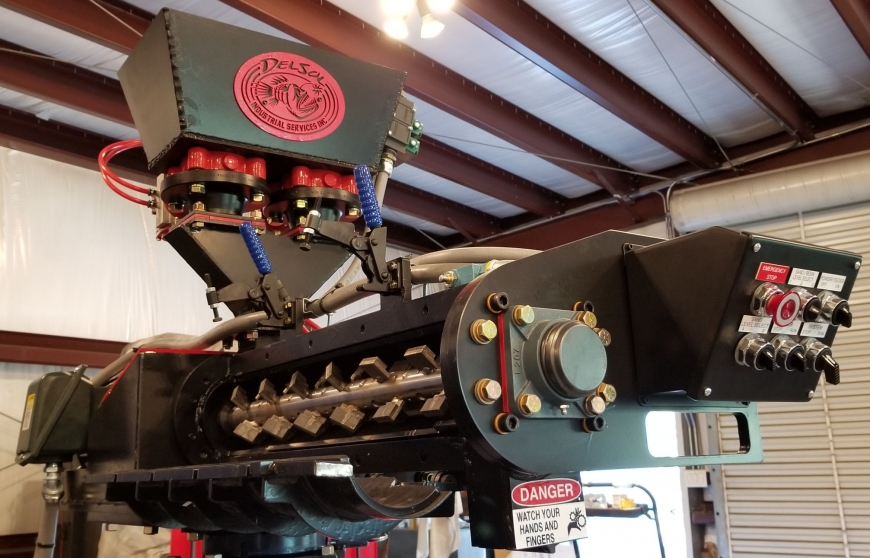

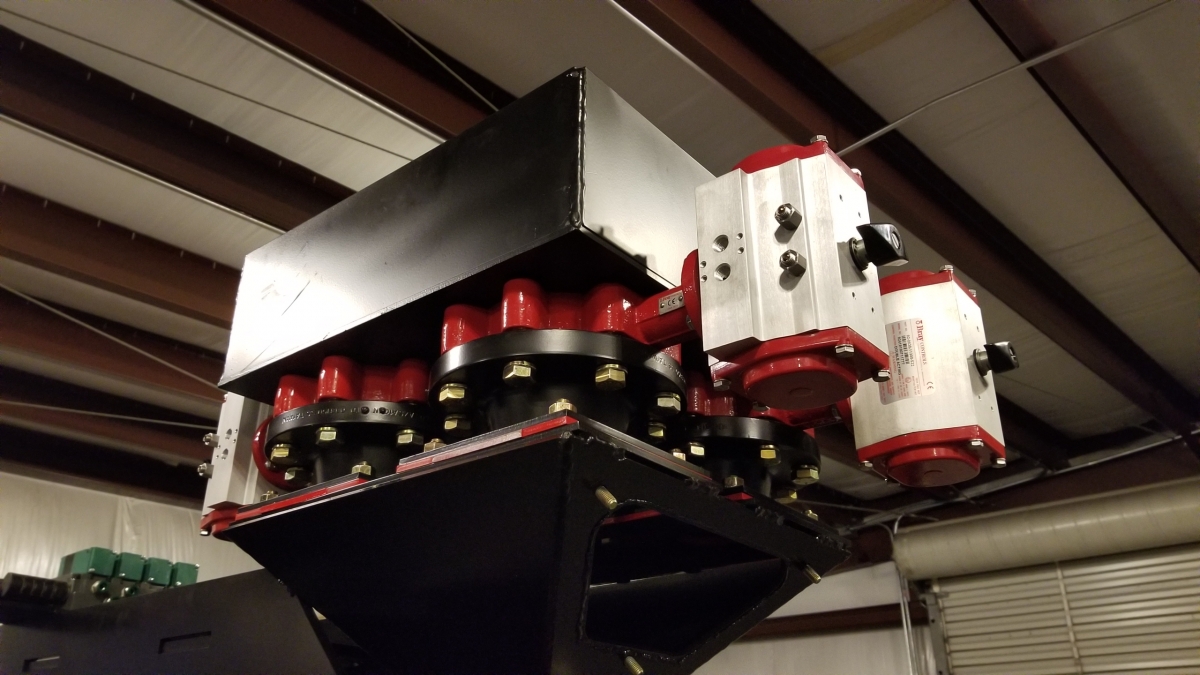

BFM100 with Dual Sandgate Option

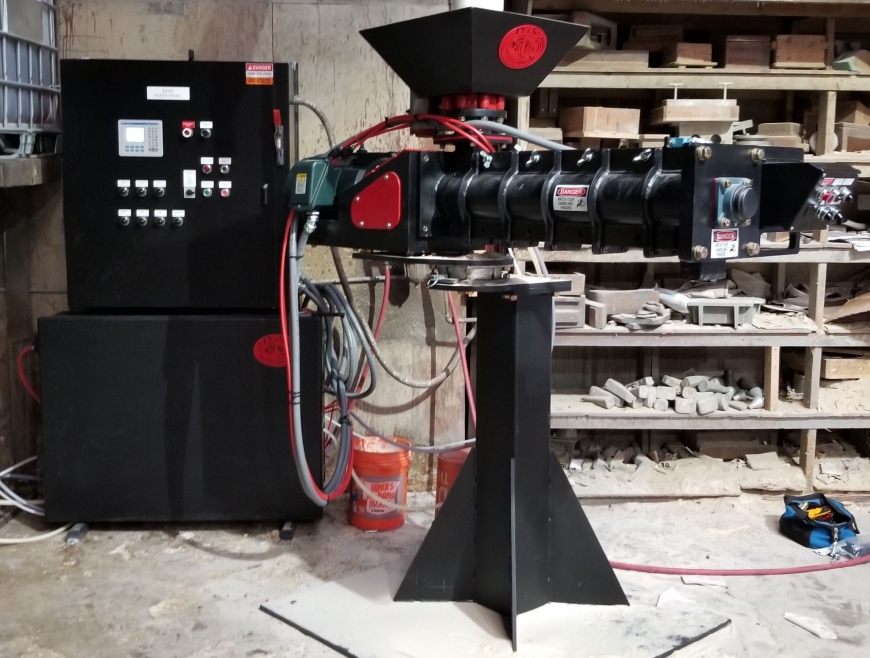

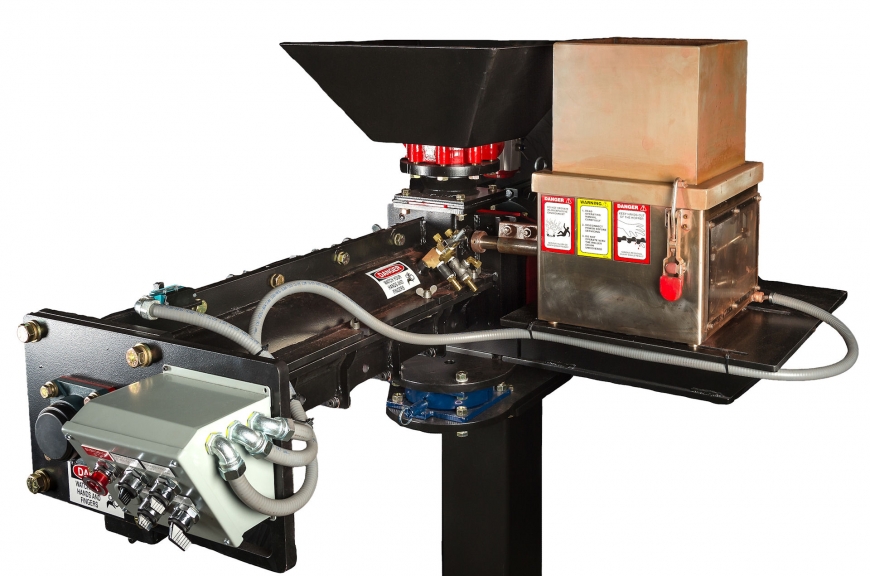

BFM250 With Swivel and Standard Mixer Control Package Shown Above

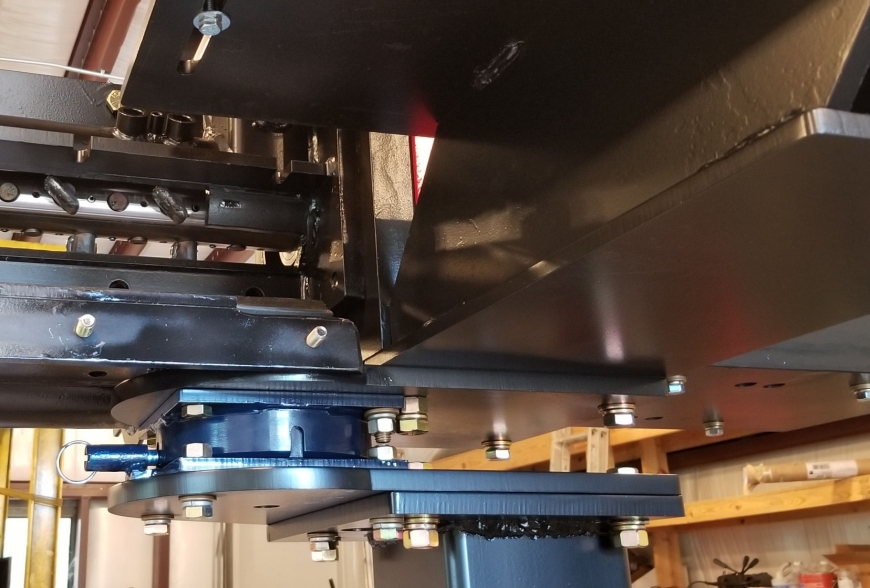

BFM750 Under Motor Swivel Configuration Shown Above

Mixing Chamber

- Direct Drive Mixing Chamber

- Dual Chamber Doors for easier cleaning and blade replacement

- CLICK FOR VIDEO SHOWING MIXING CHAMBER ACCESS

- High Horsepower Drive ensures proper mixing even at the top end of our mixer capacity ranges. Part of our design process is higher horsepower than other brands to assure you can mix even the thickest and highest resin level for the many resin systems out there.

- CLICK FOR VIDEO OF BFM750 DRIVE COUPLING SYSTEM

- Tungsten carbide tipped mixing blades.

- CLICK FOR VIDEO OF BFM100 BLADES AND SHAFT

- CLICK FOR VIDEO OF BFM750 BLADES AND SHAFT

- Precision mixing shaft assures smooth operation.

- Butterfly sand gate with independent sand metering plate. Why? Butterfly valves are resilient and don’t stick. We use Bray valves exclusively due to their high quality, durability, and availability. We use an independent sand metering plate because butterfly valves are not meant to meter - but they are great at off / on operation. So, we meter with a separate plate.

- CLICK FOR VIDEO DESCRIBING THE SAND METERING SYSTEM

- New Feature - Quick release door clamps

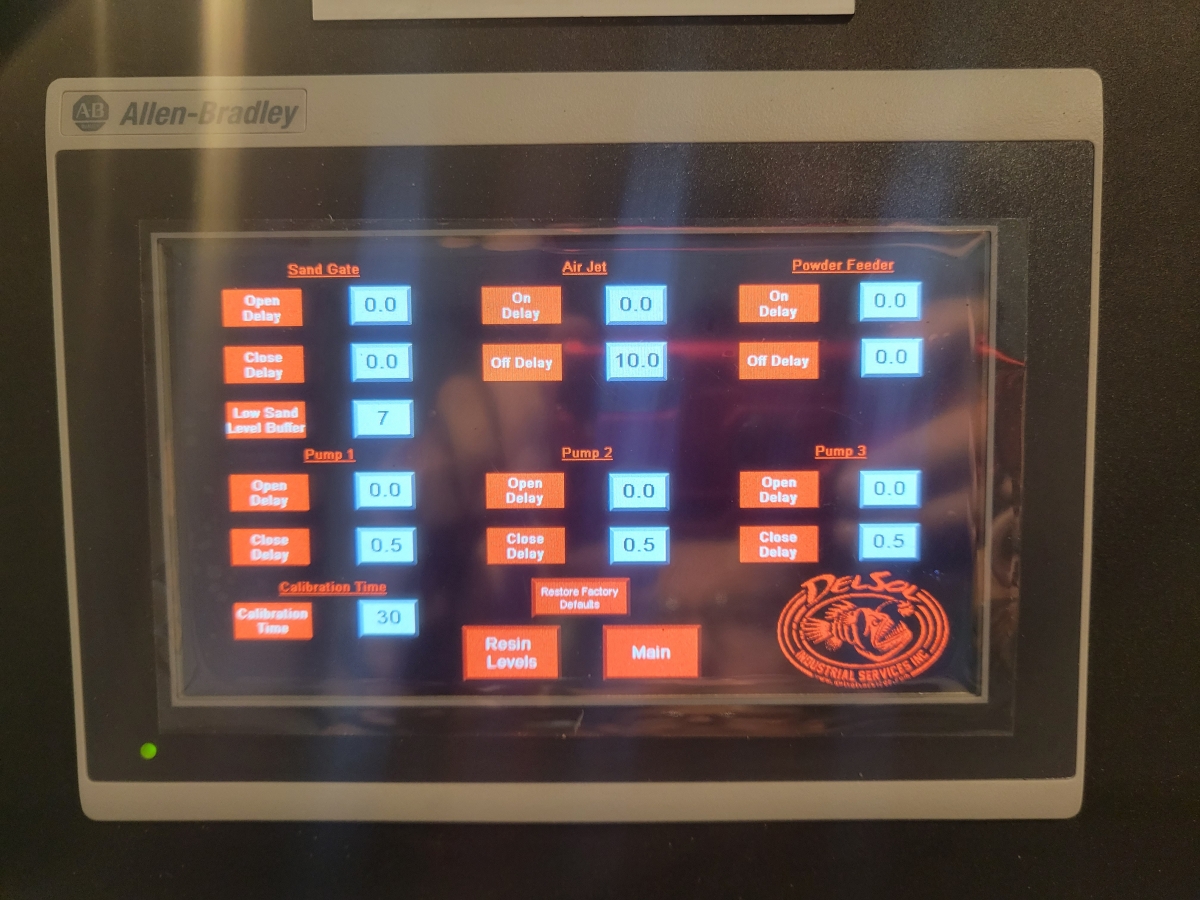

Electrical Control System

- Allen Bradley Micrologix Controller w/ Full Control HMI

- Our HMI features tactile buttons rather than touchscreens for improved durability and to prevent touch screen failure when you have resin on your fingers.

- Analog output controlled DC pump settings

- Oversized, robust NEMA components and motor starter. Old school? Yes. Flaky? No.

- Three resin levels standard

- Optional low sand interlock with reset

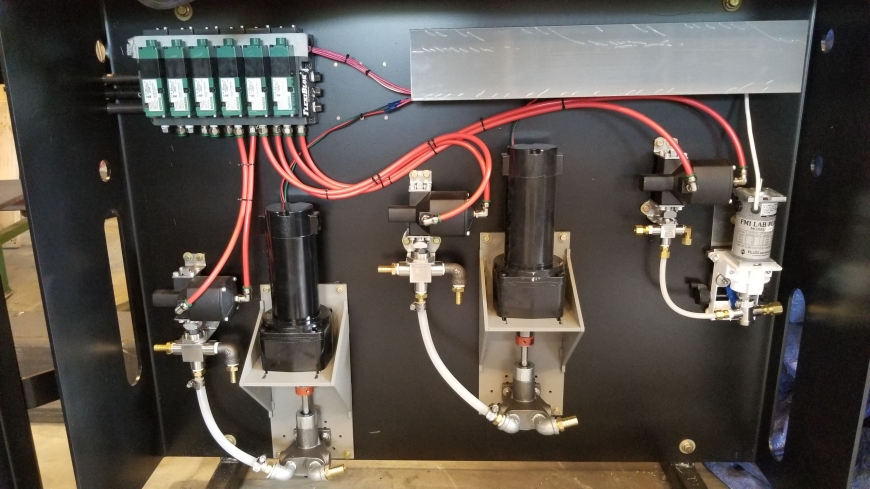

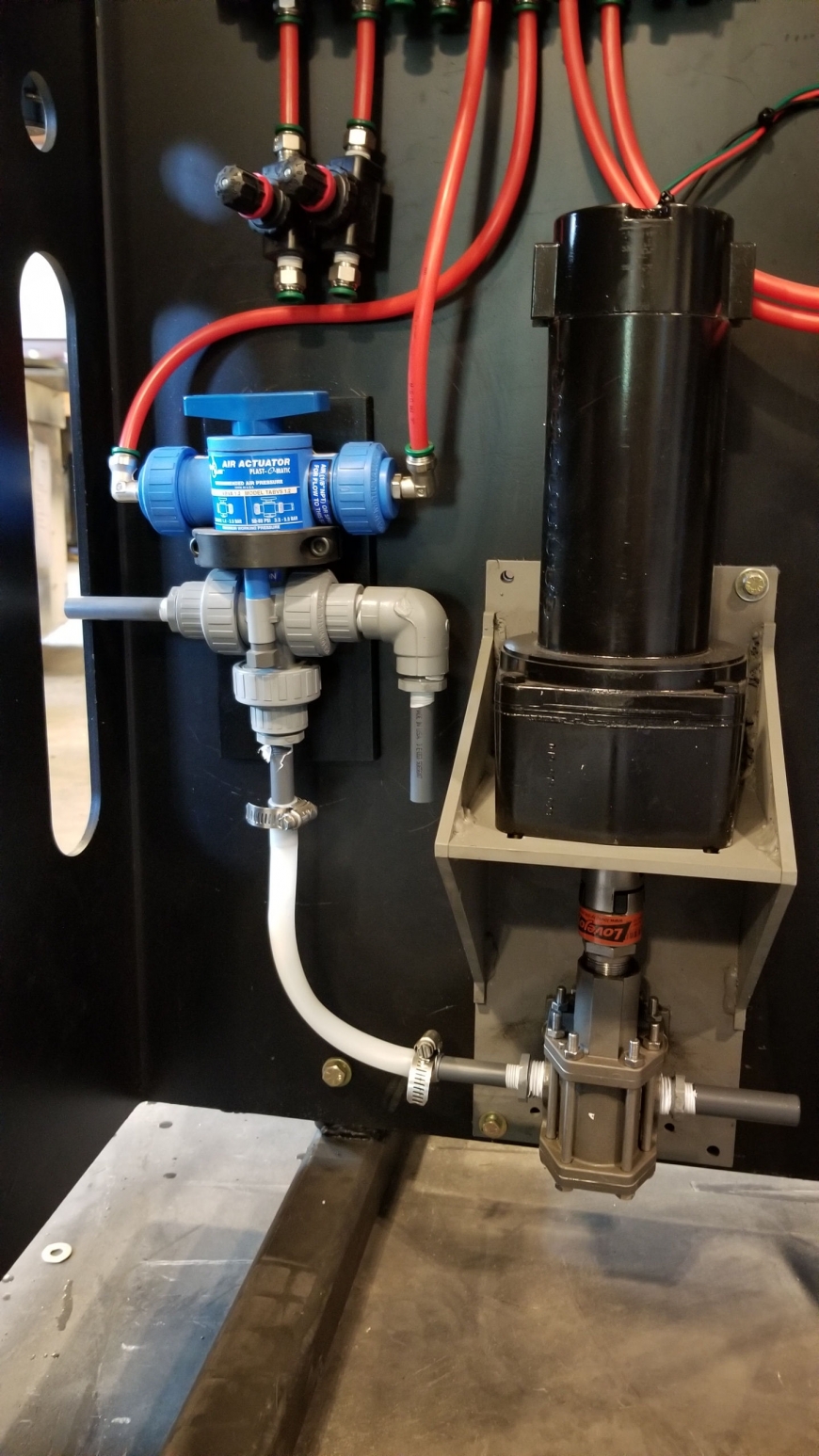

Pumping System

- Gear Motors for resin components (high torque and less susceptible to viscosity changes)

- Direct Drive Gear Pumps (so that you know they are spinning)

- Optional pumps for any resin system (Catalysts, acids, etc.)

- Integral 3 way ball valves for resin recirculation

- Integral pneumatic solenoids for air functions

Options

- Dual Sand, Dual Sand with Blend, or Tri Sand Gates

- Mixer Swivel

- Custom mixer mounting available - Below is a recent custom swivel with dual sand blend sand gates. Why? In this instance, the customer wanted the mixer to swivel but not the sane gates, so we custom fabricated the mounting to best fit the customer's installation requirements.

- Pumping Systems for any resin system

- Powder Feeders for dry powder additives properly sized for your machine.

- Sand discharge venturi dust collection system for air quality control

- Resin heating equipment

Service

While our goal is for your machine to not need a great deal of service, we do offer field service technicians for both new and existing machines. The components we build with are readily available and are normally off the shelf. Del Sol stocks parts for the machines we sell, but if you are in a pinch, most can be bought from major industrial supply houses.

Warranty

One year warranty on machine with the exception of wear items (blades, pumps, ball valves, tubing, air devices). However, if you supply dirty power or air to the unit, you are responsible for the negative effects of that. If you tell us about air and power issues in advance, we will supply the needed items to clean up power and air for the machine at an additional charge.