Del Sol Industrial has added foundry resin heating systems to our equipment lineup.

We spent a great deal of time simplifying these systems and producing them to operate in the reality of a foundry operation. They are simple, robust, and easy to use. They are also safe. We have carefully selected the heating method to assure safe operation.

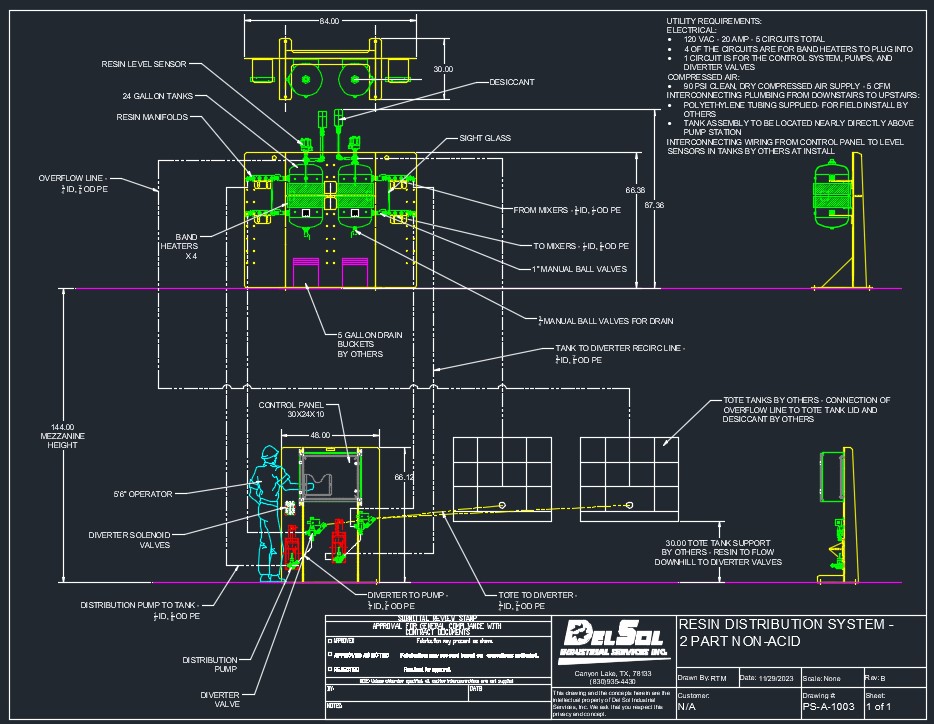

Below is a drawing of a unit that we developed for a cold box core room (two part phenolic urethane). The system includes heated tanks for the mezzanine level and bulk resin transfer pumps at floor level to transfer resin from tote tanks to the heating tanks upstairs. We utilized a recirculating delivery system so that the tanks and resin in the lines are always at a homogenized temperature. We also always use recirculating pumps for the mixers that draw this resin. Using this method, all of the resin in the system is at your preset temperature.

Further, the tanks are "kept full". Whenever a batch of sand is made, the tanks automatically refill that small amount of resin so that you don't see surges of cold resin hitting the system.

The heaters are wrapped around the tanks so you are not constantly gunking up heating elements and potentially exposing the resin to a direct heat source.

Systems are available for any foundry binder system and we will custom design to meet your exact requirements, tank size, and level of sophisitcation on resin temperature control. Anything from simple thermostats (pictured below) to PID temperature control are available.