Del Sol Proudly represent EMI (Equipment Merchants International) for its full line of cold box and hot box core machine offerings. EMI offers fully refurbished Shalco shell core machines to handle each of your unique shell core needs. Each shell core machine offers different features and options to fit your needs.

U-150

The Shalco U-150 provides a new dimension in shell core machines. This compact machine is small enough to fit into practically any production layout and supplies the need for small and medium size cores and molds of the highest quality. It offers the same speed and accuracy found in larger Shalco machines but with small machine economy and convenience. Right and left hand models are available for one-man multiple machine installations. The U-150, like all Shalco models, is backed by EMI’s experienced engineering, manufacturing and service organizations.

U-180

Constructed of heavy iron castings and, like all Shalco Core Blowers, the U-180 is manufactured with machine tool precision to provide sustained accuracy and long production life. Its operation is fully automatic and allows the attendant to attend two or even three machines since it is only necessary for him to return to each machine to remove the finished cores. Not only does this machine produce shell cores of the highest quality with all the inherent advantages of lightness and strength found in the modern method of shell core production, but at the same time it allows integration into automated production lines.

U-360

Shalco foundrymen faced with the problem of producing large, heavy cores can take full advantage of the benefits inherent in the shell core-making process. The Shalco U-360 was developed specifically to cut the cost of big castings… has already proved itself in foundries around the world. It’s a rugged machine, built to deliver long trouble-free service under the most demanding operating conditions; yet it offers the same precision and operating smoothness found in medium and small-size units.

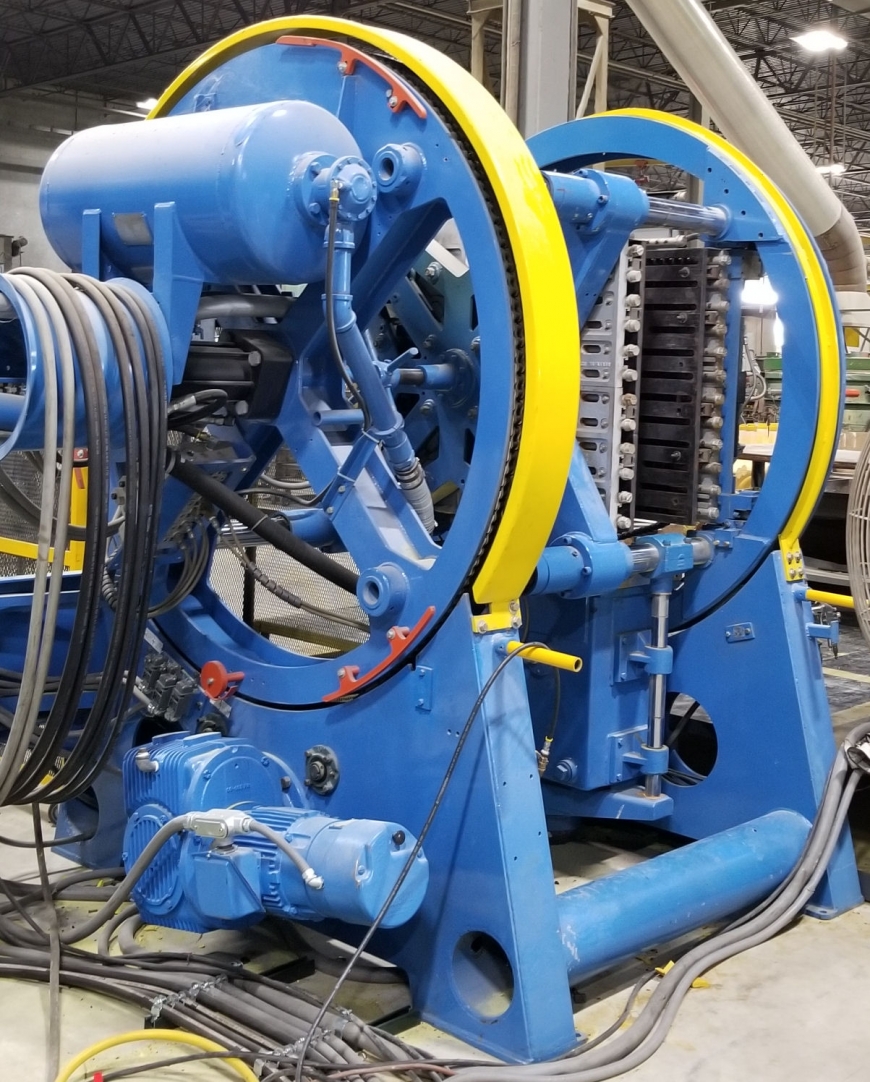

U-900

“Shalcomatic” totally mechanized Model U-900 machines are used to produce a wide range of precision shell cores/molds on a mass production basis. No operator is required. Finished cores/molds are automatically and gently ejected onto the flexible conveyor belt of the machine for removal by an attendant for immediate transfer into the main cross-conveyor system for distribution.

Complete flexibility is provided to accommodate a variety of shell cores or molds to suite every foundry requirement. Individual thermostatic temperature controls on each heater plate…timers for blow,invest, cure, and rock cycles.

All machine motions fully automatic…At the completion of the cure time the core is retained in the movable half of the core box. Core box then rotates 90 degrees and ejects cores onto a conveyor raised into a receiving position.

Conveyor retracts to original level and delivers cores to the attendant.

Contact Del Sol Services today to learn more.