Dealing with spent foundry sand has always been a challenge, but with environmental regulations getting more stringent all the time, reclaiming one's sand is becoming much more critical to success than ever.

To aide in sand reclamation, Del Sol Industrial strongly recommends Didion rotary reclaimers for no bake and greensand operations.

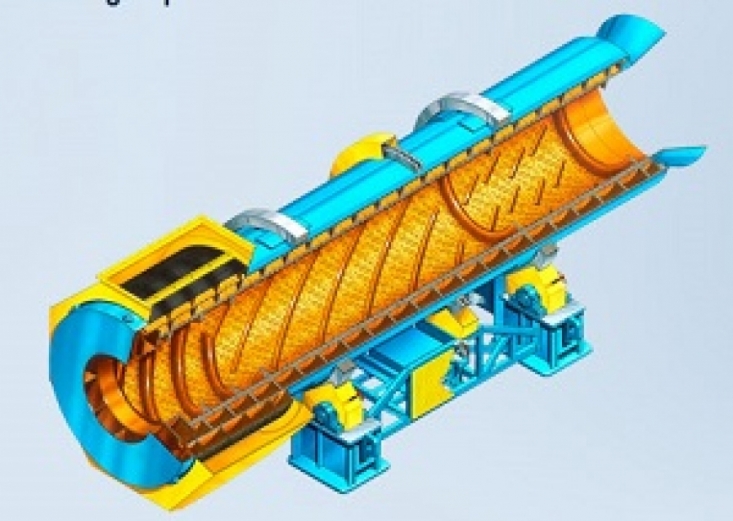

Didion Rotary Lump Crusher

The DIDION Rotary Lump Crusher / Sand Reclaimer represents the lowest maintenance and most reliable foundry sand reclaimer in the industry. It is environmentally friendly (sealed design with serious dust collection hood) and has the lowest operating cost per ton, worldwide. It crushes, scrubs, separates, screens and classifies large mold lumps into reusable grain size sand while discharging tramp metal, rebar, chills, and debris out the end with a simple change of rotation direction.

Standard models process lumps from 2 to 60 tons per hour either in batches or continuously and the versatile design allows sand to be discharged at either end. Custom machines can also be built to accommodate specific applications.

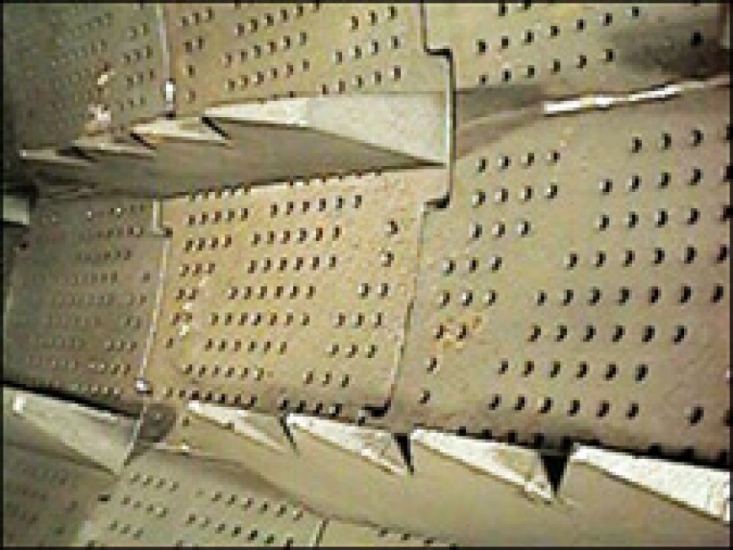

Attrition Chamber

The attrition chamber features perforations that transport sand to scrubbing chamber. The DIDION's extra heavy duty construction saves on maintenance and reduces downtime while its efficient design minimizes utility costs and dust. Plus, since no operator is required, extra labor savings can be enjoyed. With an optional variable jet burner, one can even reclaim wet, outside and dump sand as well. Installation is simple as the DIDION Lump Crusher / Sand Reclaimer requires no pits or special foundations in most installations.